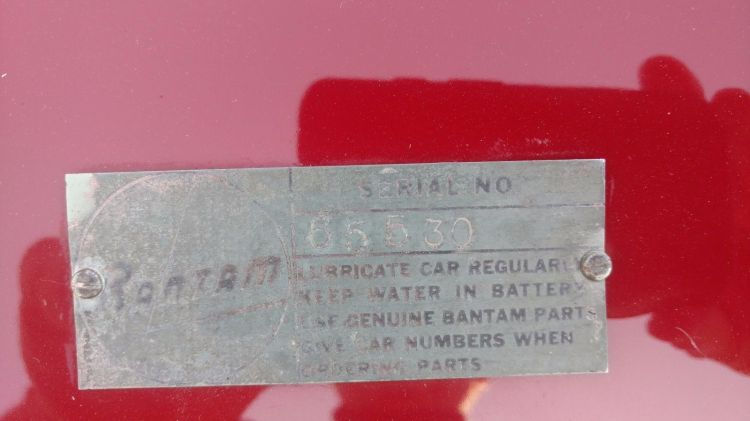

American Bantams are small cars which can be simpler projects than many of the other cars from the same era; they have very limited trim, they share a multitude of parts with other vehicles, they have far fewer parts then other cars, and most of those parts are a very manageable size. Even better for the restorer, Bantam was a company which was known for going to the local hardware store to get bits to keep the line running. Despite these positive attributes, don’t let the Bantam’s smart looks make you believe it won’t be challenging. In fact, there are some parts which you will encounter along the way which are sure to provide a challenge to any restorer. How do you overcome these challenges? Patience.

While I could go on about what parts may be challenging, I will tell you the story about my efforts over the last year to reproduce cross-members for Bantam Commercial vehicles and four passenger convertibles. All of the other models used some variation of C-channel as the rear cross-member, a simple solution. The cross-member I needed was 1 5/16″ steel tube, bent in four places, and flattened at the ends. On trucks, it served as part of the spare tire holder and on the passenger cars, it served as a rear cross-member that didn’t interfere with the rear seats.

A Bantam Commercial crossmember in its natural habitat, a 1939 pickup truck.

With light kinking in each of the bends, I figured this is something which should be easily made. I considered a Harbor Freight pipe bender, but decided against it due to the small radius of the bends. I contacted people who built race car roll cages, they didn’t want to touch it. Thinking of universal engine swap cross-members, I even contacted a number of aftermarket companies, who also wanted to stay far away from the project. One race car chassis company offered to do it, but I never heard back from them after sending over a few photos of the part.

I realized I had to be missing something, it’s just bent pipe, there must be some way to have this made. Being located in New York, I contacted a number of tube bending facilities. The best I could find was a company which was willing to make 1,000 of the cross-members. That would mean I would have enough units to replace the cross-members in 1/6 of the total Bantam production run.

After nearly giving up and preparing myself to accept a fresh piece of c-channel, I decided to make a few calls. I went to google and typed in many variations of pipe bending or tube bending. A company in Olean, New York said they may be able to do it but suggested another outfit who may be more inclined to take on the project. It took me a while to get the sample to this other company to see what they could do.

Two weeks after getting my sample to the company, they had manufactured the component parts of two sets of prototype cross-members for me.

My sample Bantam Crossmember which had seen better days and a couple of components to build two new sets.

To see how they fit, I unpacked them and brought them over to the shop project. I’ll let you tell me how you think they fit.

I’m personally very happy with these parts. My top goals were to have pieces made which looked identical to the original units while being substantially stronger and while remaining affordable. These were a little more costly than I would have liked, but the manufacturer nailed my other two goals so well that the higher price isn’t as painful. The only part which is visibly not original is the lack of a drain hole in the large tube. This is something another person can add to their cross-member if they really want to have it.

I will need to fit them to the chassis and determine a few final details by installing these into the chassis of the shop project. I’ll be posting detailed instructions of how they are installed once they are finalized.

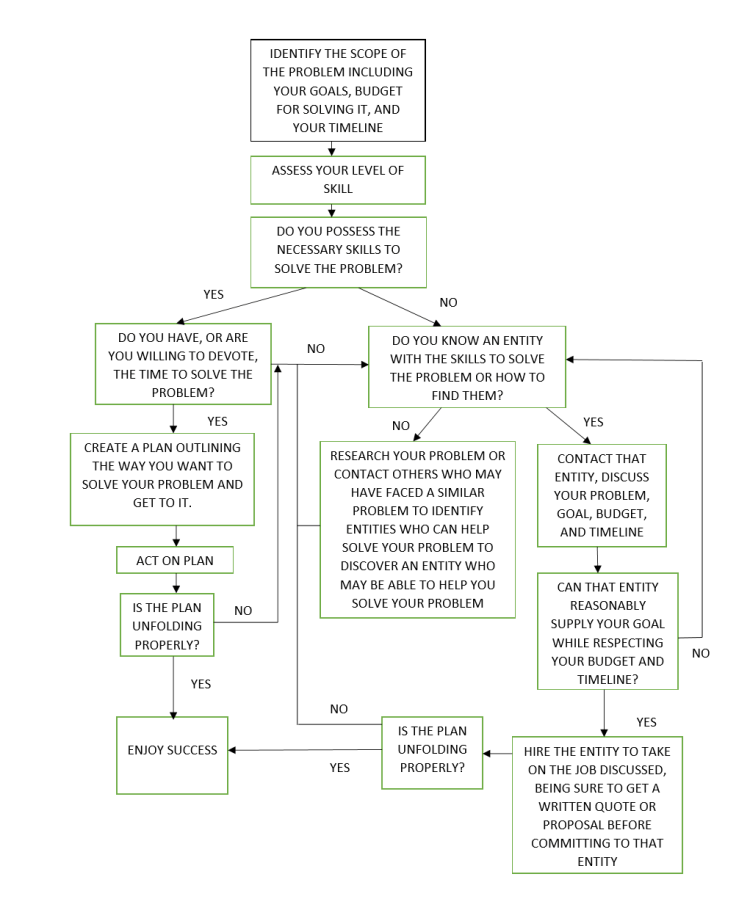

The point of this article has nothing to do with the excellent quality of these reproduction cross-members, even though they are substantially beefier than the originals. The point here is that there are very few things in a project that cannot be done if you are patient, make a reasonable assessment of your skills, and have the resources to make it happen. Here is an overly simplified flow chart indicating a helpful process for reaching each of your goals:

Here is an illustration of how I perceive my path through this flow chart in pursuing a rear cross-member:

As you can see, I got stuck in the research loop for a while, but in the end it paid off. Researching or contacting other may even lead you to a finish product ready to solve your goals or a person willing to take on your project and do the necessary leg work. Also, as always, one of the best things you can do is join both of the clubs. More than likely, someone has been in the same boat as you. If that person has never found a solution to their problem, perhaps together you can. Or, perhaps they have found just the solution you have been waiting for. For instance, if you contact me for a rear cross-member for a Bantam Speedster, a set of brake cables, or 100 new Bantam headlight lenses; I can help you. If you need something else, I can certainly try to help you or point you in the right direction.

Enjoy your weekend!